In view of the maintenance of the full hydraulic tunnel prospecting rig produced by Jiexing Drilling rig Factory in Chifeng, the following points are briefly summarized:1. Replace the oil suction and return filter element regularlyThe new equipment manufacturer comes with two oil return filters. Rep....

![]() 2023-07-23

2023-07-23

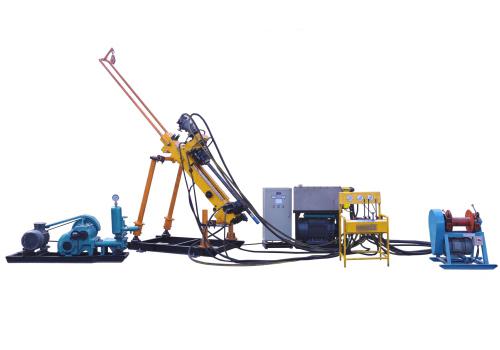

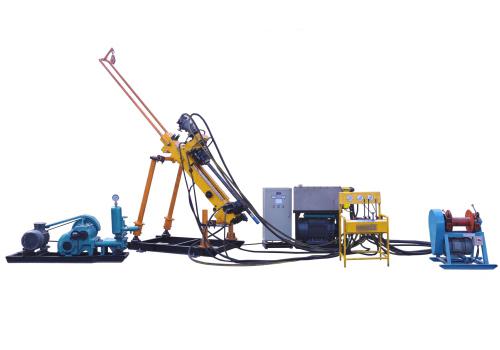

Chifeng is the birthplace of tunnel drilling rig, led by Guilin Research Institute in the 1970s, Chifeng non-ferrous metal mine drilling rig repair factory is the only designated production unit of national tunnel drilling rig, after 30 or 40 years of industrialization after reform and opening up, C....

![]() 2023-07-23

2023-07-23

In recent years, due to the continuous innovation and upgrading of surface exploration drilling RIGS, crawler drilling RIGS have also appeared on the market and become more or less mentioned topics in the drilling circle. The advantage of full hydraulic crawler drill is that it is convenient to move....

![]() 2023-07-23

2023-07-23

Many users and rig manufacturers in order to move, walking convenience, the tunnel rig refitted on the track. In order to adjust the Angle, the cylinder hydraulic lift. Shallow holes do not need to consider stability, even if the stability is poor, it can also meet the drilling engineering design ho....

![]() 2023-07-23

2023-07-23

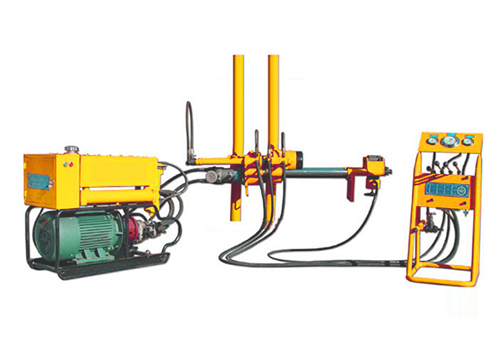

The gripper of the full hydraulic tunnel prospecting rig is an important executive assembly of the main engine. When drilling, lifting, pulling and torsional unloading of drill pipe, it is necessary to work together with chuck, gripper and feeding device.According to the principle of the system, the....

![]() 2023-07-23

2023-07-23

Tunnel drilling machine is suitable for indoor use with complete roof without breaking, no quicksand and no support. Drilling in different angles of 360° in the roadway has different requirements for chamber size.1. Horizontal forward drilling, the chamber requirements are not less than: 2 meters h....

![]() 2023-07-23

2023-07-23

Each mine geological exploration project is inseparable from the system and process, safety issues have always been the topic of use throughout the construction site, geological drilling practitioners in the construction site, both to safety, strengthen safety and civilization construction, but also....

![]() 2023-07-23

2023-07-23

The application of rope coring technology in tunnel drilling rig is relatively late, at first it was only applied in vertical shaft surface drilling rig, engaged in geological exploration of vertical holes on the surface. The full hydraulic tunnel drill is used in the tunnel to drill horizontal hole....

![]() 2023-07-23

2023-07-23

First, diamond drill preparation:1. Check whether the last diamond bit has any damage to the bit body, tooth loss, etc., to ensure that the bottom of the well is clean and there is no falling object.2. Carefully transport the diamond bit and place it on a rubber pad or wooden board.3. Check whether....

![]() 2023-07-23

2023-07-23

1) In order to ensure the tightness of the hydraulic control system, the number of disassembly of the tubing joint is usually reduced as far as possible. Hydraulically operated valves, feed cylinders and instrument panels should not be removed from the frame as much as possible when the parts are di....

![]() 2023-07-23

2023-07-23

1) In order to ensure the tightness of the hydraulic control system, the number of disassembly of the tubing joint is usually reduced as far as possible. Hydraulically operated valves, feed cylinders and instrument panels should not be removed from the frame as much as possible when the parts are di....

![]() 2023-07-23

2023-07-23

The hole accident is a common event in the geological exploration industry. Hole collapse drilling and drilling clamping are also the most common types of hole accidents, which will bring immeasurable losses to geological exploration, survey target tasks and drilling construction teams.The occurrenc....

![]() 2023-07-23

2023-07-23

(1) Composition and classification of diamond bits1. Composition of diamond bitDiamond drill is a tool for diamond drilling broken rock, it is composed of three parts, namely:1 - Diamond; 2 - carcass; 3 - Drill body2. Classification of diamond bitsAccording to the different parts of the diamond coat....

![]() 2023-07-23

2023-07-23

The choice of the diamond bit used in the formation phase is a key factor affecting the drilling, and the quality and efficiency of the drilling directly affect the quality of the geological report and the exploration cost. When choosing a diamond drill bit, people often expect it to have high timel....

![]() 2023-07-23

2023-07-23

The full hydraulic tunnel prospecting drill is grinding into holes by rotating and pressing the rock wall of the diamond bit. Usually hard rock with softer hardness of the diamond bit, soft rock to use a bit with greater hardness of the matrix. After so many years of drilling experience, these basic....

![]() 2023-07-23

2023-07-23

Referring to the full hydraulic portable drilling rig, it is a prospecting drilling rig product that has emerged in recent years and developed relatively fast. It is mainly used in non-coal mine surface exploration projects. It can be said that its birth on the vertical shaft surface drilling rig ma....

![]() 2023-07-23

2023-07-23

In recent years, due to the continuous innovation and upgrading of surface exploration drilling RIGS, crawler drilling RIGS have also appeared on the market and become more or less mentioned topics in the drilling circle. The advantage of full hydraulic crawler drill is that it is convenient to move....

![]() 2023-07-23

2023-07-23

With the development of the domestic geological exploration industry in recent years, it has also driven the development of the prospecting rig manufacturing industry like bamboo shoots, which marks the continuous improvement of China's industrial level and the prosperity of national industry, a....

![]() 2023-07-23

2023-07-23

1. The main machine of the full hydraulic tunnel drill is composed of a gyro, a gripper, a feeding device and a frame, and it is convenient to install and disassemble between each part.1.1 Power head The power head consists of a tilting variable piston motor, a gear reducer and a cone-sleeve hydraul....

![]() 2023-07-23

2023-07-23

Mine full hydraulic tunnel prospecting rig products related to deep hole drilling:There are three core elements: torque and speed, clamping force, lifting and feeding force.There are three core technologies: hydraulic control system, return oil cooling and filtration system, and hydraulic actuator.H....

![]() 2023-07-23

2023-07-23