With the development of the domestic geological exploration industry in recent years, it has also driven the development of the prospecting rig manufacturing industry like bamboo shoots, which marks the continuous improvement of China's industrial level and the prosperity of national industry, and gradually narrowed the gap between the international advanced level.

However, in the face of a wide variety of hydraulic drilling RIGS on the market, people often do not know where the difference between different types of drilling RIGS is, although they are all geological exploration equipment for prospecting and core extraction, what are their respective characteristics?

First of all, the full hydraulic portable drilling rig, of which the full hydraulic represents hydraulic control, and portable as the name suggests refers to the convenience of human handling, in addition, this type of drilling rig is the top drive design, the application of thin-wall drill pipe, drill tool, the use of mud materials in the drilling process, through this method to achieve more ideal drilling efficiency, known for high-speed drilling. It is important to note here that portable and crawler RIGS are two different concepts. The advantage is that under better geological conditions, the rock is not broken or there is no large crack, the formation is not too hard, the drilling speed is relatively fast, and the ideal drilling depth can be achieved, but it is not suitable for hard and complex formations. Portable hydraulic control part, each action of the drill is controlled separately, can not be hydraulically linked, twist and unload drill pipe by manpower.

The origin of full hydraulic tunnel prospecting rig is relatively early in China, we all think that it is only in the tunnel to achieve arbitrary inclination drilling exploration, in fact, there is no space restrictions on the surface drilling will be more convenient, that is to say, the tunnel drilling rig must be drilling on the surface, and the surface drilling rig may not be constructed in the tunnel.

In addition to drilling in any direction, in fact, its biggest feature is that it can achieve mechanical torsion discharge of drill pipe, drilling and lifting through hydraulic linkage, reducing the workload of people, and its hydraulic system is more advanced, called "full hydraulic".

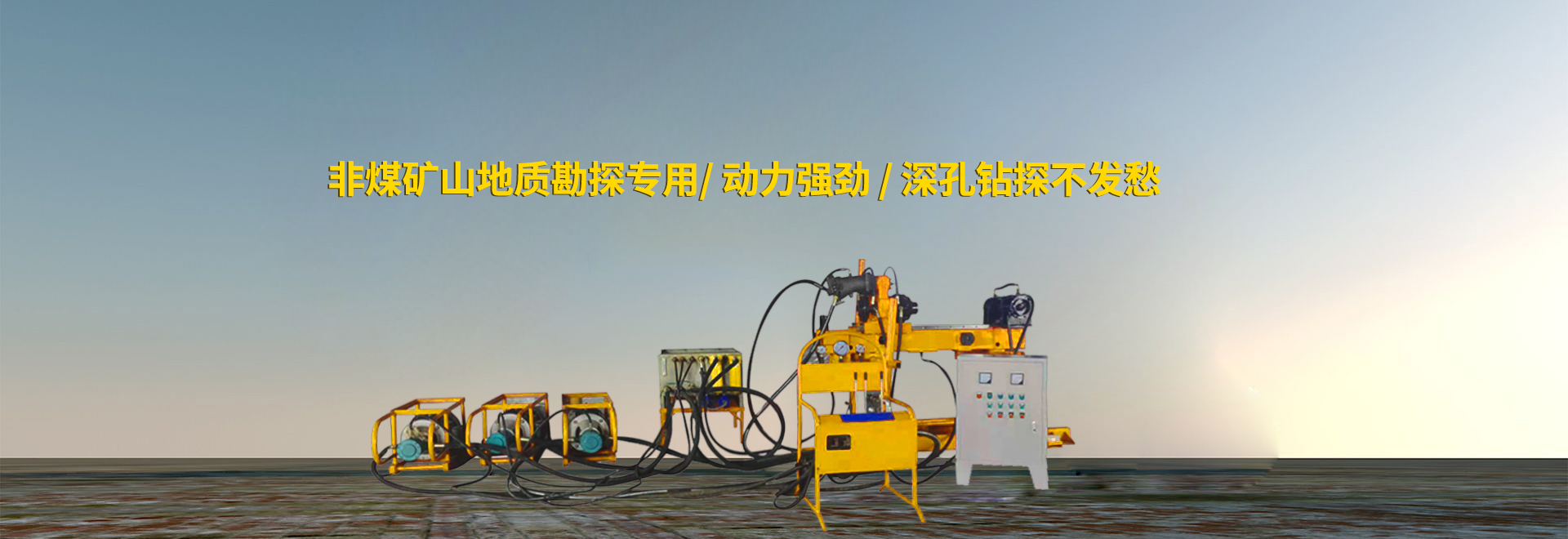

In addition, the non-coal mine tunnel drilling rig produced by our company uses a quantitative oil pump to supply oil, manual variable motor to drive the spindle rotation, can be considered by the hand wheel according to different geological conditions to choose a more suitable speed and output torque, in most geological conditions can meet the design depth requirements, do not pick the formation.

Φ75mm diameter, rope coring drilling depth within 800 meters, whether it is surface exploration or drilling in the mine shaft and tunnel, there are greater advantages.