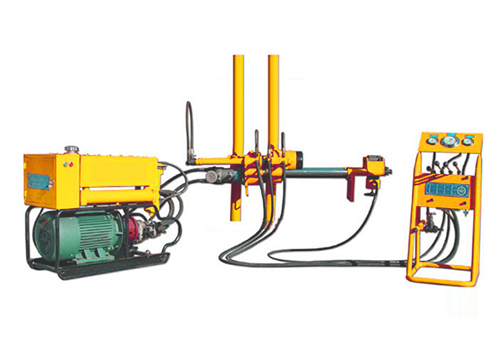

1. The main machine of the full hydraulic tunnel drill is composed of a gyro, a gripper, a feeding device and a frame, and it is convenient to install and disassemble between each part.

1.1 Power head The power head consists of a tilting variable piston motor, a gear reducer and a cone-sleeve hydraulic chuck. The motor is decelerated by two gears to drive the main shaft and the hydraulic chuck to realize the rotation of the drill tool. Adjust the motor displacement to adjust the speed and torque. The power head spindle is hollow shaft structure, the diameter of the through hole is 75.8mm, the replacement of different diameter chuck slips can use Φ60mm, Φ47mm conventional drill rod, the length of the drill rod is not limited by the size of the structure of the rig itself, the power head is installed on the tray of the feed frame, with the aid of the feed cylinder along the guide rail of the body to achieve the drill tool feed and pull. The body stiffness is good, and the operation is smooth. The hydraulic chuck adopts the cone-sleeve type to realize the structure of hydraulic clamping and loosening. It has the characteristics of automatic centering, safety and reliability, and large clamping force. It can not only ensure normal drilling, but also can be used for lifting drill tools and strong pulling.

1.2 The gripper adheres to the normally closed structure of disc spring clamping and hydraulic release. It can prevent the drilling accident caused by sudden power failure when pulling down the drilling tool. The gripper is fixed in the front end of the body of the feed device, and hydraulically linkage with the small chuck cylinder and the feed cylinder during drilling and lifting. The clamping force is large, the clamping is reliable, the sensitivity is high, and the drill pipe is not damaged.

1.3 The feeding device adopts the oil cylinder to push and pull the support plate and the power head directly to move forward and forward along the guide rail of the feed frame, and the connection between the power head and the support plate is similar to the open box type of the vertical shaft drill. The supporting plate is strung together with the power head with a pin on one side, and the power head box is connected with the supporting plate with a hinged bolt on the other side. The feed fuselage is fixed on the beam of the ground support through the pipe clamp or on the column through the rotary head and the rotary sleeve.

1.4 Column, ground support telescopic column has two specifications, and 1.8-3.2m and 3.2-4.5m, used for the installation of the main engine in the tunnel, according to the specifications of the tunnel to choose the size of the telescopic column. The surface support can be used either in the tunnel or on the surface, and can also be drilled at any inclination Angle. The ground anchor is used to fix the surface support.

2. Control console The control console is the control device of the rig. It is composed of various control valves, pressure gauges and pipe fittings. The linkage function of turning, feeding, pulling, chuck and gripper of the rig is realized by the combination of valve components on the control table. On the operating table, there are motor rotation, cylinder feeding and pulling, drilling and drilling change and stop valve. Rotary pressure, feed pressure, mud pump water pressure can be displayed on the operating table panel. The tubing is arranged neatly with signs indicating the connection method. Various oil circuit control valves are installed in the frame of the control console. High pressure hose adopts threaded connection. When disassembling the tubing, use its own plug to block the outlet of the tubing two joints to avoid the leakage of oil in the pipe and the stolen goods into the pipe.

3. Hydraulic station The pump station makes the power source of the drilling rig, and has the role of cooling and ensuring the cleanliness of the hydraulic oil, which is composed of the oil pump, the oil tank, the cooler, the oil filter, the base and other parts. The motor drives the oil pump through the NL coupling, absorbs oil from the oil tank and discharge high-pressure oil, and drives each actuator of the rig through the control console. The oil tank is a container that holds the hydraulic oil and is placed above the oil pump. In order to ensure the normal operation of the hydraulic system, a variety of protection devices are provided on the oil tank. Such as: oil suction filter, return oil filter, cooler, air filter, oil temperature gauge, magnet, etc., in order to avoid the stolen goods in the underground refueling into the tank, can be refueled through the air filter.

In summary, the drilling rig has the following characteristics:

a, the rig is composed of three major parts, that is, the main engine, the pump station, and the control console, which can be flexibly manipulated according to the site conditions; Good disintegrability, convenient relocation and transportation.

b, mechanical unscrewing drill, can reduce the labor intensity of workers, improve work efficiency. The gripper slips can be easily removed, the diameter of the through hole is enlarged, and the rough drilling tool is easily lifted.

C, single cylinder directly feed and pull the drill tool, simple structure, safe and reliable, feed, pull capacity is large, improve the ability of the drill to deal with accidents.

D, the use of double pump system, rotation parameters and feed process parameters can be independently adjusted. Variable oil pump and variable motor are combined for stepless adjustment, and the speed and torque can be adjusted in a wide range, which improves the adaptability of the drill to different drilling processes.

e, the diameter of the rotary hole is large, the replacement of different diameters of slips can use different diameters of drill pipe, the length of drill pipe is not limited by the structural size of the drill itself.

f, using the support cylinder to adjust the fuselage Angle is convenient, labor-saving, safe and reliable.

g, through the control console for centralized operation, personnel can be away from the hole a certain distance, which is conducive to personal safety.

h, hydraulic system protection device is completely stable and reliable, strong versatility.