In recent years, due to the continuous innovation and upgrading of surface exploration drilling RIGS, crawler drilling RIGS have also appeared on the market and become more or less mentioned topics in the drilling circle. The advantage of full hydraulic crawler drill is that it is convenient to move, saving the time of moving holes and equipment installation, so it is also favored by some users.

"Crawler" refers to the rig equipment installed on the chassis assembly of the track, mainly considering walking. There are many people in the geological exploration industry who may not consider all aspects of the selection of prospecting RIGS. Here are some ideas and arguments that are particularly valuable to share:

1, the drilling part is the drilling part, the walking part is the walking part.

The rig part is the main part of the geological exploration operation, which is the factor we should pay attention to. Drilling engineering design hole depth, drilling diameter and drilling orientation and the total amount of engineering is an important basis for the selection of exploration equipment, combined with geological conditions, to comprehensive consideration. According to the actual use requirements, first consult the relevant technical parameters of the rig to see if the rig can meet the needs of this drilling task, if the actual clamping force, lifting force and torque of the selected full hydraulic crawler rig can not meet the requirements, then even what is the use of a crawler device?

The walking part is an accessory device that serves the entire drilling operation and can be used as a reference factor.

2, crawler type full hydraulic drill walking convenience does not mean easy to work.

The application of crawler travelling chassis in full hydraulic drilling machine must consider the practicability of actual drilling operation, and can not put the cart before the horse. For example: whether it is convenient to unload the drill pipe, whether it is convenient to lift the core, whether it is convenient to drill the holes in different directions, whether the distance between the machine head and the hole mouth is appropriate, and many other factors, if the full hydraulic drill is refitted on the track chassis assembly, it causes inconvenience to the actual operation, and can not shake off the work with a big axe, then what is the meaning of the track drill?

Portable drilling machine is based on vertical downward holes and inclined downward bearing holes, and is the top drive connection, so in the power head and the gripper between the manual twist off the drill pipe, installed on the crawler walking site operation is more convenient, but the full hydraulic tunnel prospecting rig is hydraulic linkage design, rely on machinery to drill, drill and twist off the drill pipe, so the small union in the power head behind the drill pipe up and down, In addition, the track chassis has a height of about 60 cm, so if there is no platform, there is a situation of climbing.

3, portable drilling rig why to install a tracked chassis?

The real portable drilling rig does not need to install a track chassis, because the intention of "portable" is to facilitate manual handling, and it considers the equipment relocation and installation problems. Then some people will say: "crawler drilling rig does not require manual handling, equivalent to a new upgrade on the basis of portable." The logic is right, just from a relocation point of view it is a step up. So let's think about it, why doesn't Ingle drill mainly push crawler drill products?

Portable drilling machine production of material and heat treatment requirements are very high, only to achieve compact size, light weight, high strength in order to achieve real portability, which is the embodiment of the strength of the manufacturer, not an empty talk. So many lack of funds, the technical team is backward, the production process and research and development ability is backward, and the enterprise management concept is backward. Some of the top drive drill products produced by the rig manufacturers will certainly use thicker steel plates and thicker steel to make up for the lack of strength and rigidity, so the large weight and size are no longer lightweight design products, and the true meaning of "portable" has been lost. Then, when engaged in geological exploration work on the surface, relocation has become a problem, so the appearance of the caterpillar chassis assembly solves this problem.

The price connotation of a rig comes from its core value, not from the weight of the rig itself.

4, What kind of construction site is suitable for crawler drill?

The first thing worth affirming is that "track type" is indeed a novel and convenient good product concept. Conventional surface exploration engineering relocation of more than 100 meters deep is not the main problem, the main consideration of drilling efficiency, can not consider the retrofit caterpillar.

Special use conditions, no track walking part can not reach the work site, must consider retrofitting the track, drilling efficiency is a secondary factor.

The depth of less than 100 meters, relatively dense survey, exploration holes, relocation and installation occupy a relatively large proportion of the project, it is recommended to modify the crawler.

5, although there is a track walking device, but do not expect all the supporting equipment installed on it, it is not all-around.

We must objectively understand and use crawler walking products, sometimes fish and bear's paw can not be both, because the configuration of the full hydraulic drill must first consider the drilling capacity, followed by the structural size, to meet the drilling task conditions of the rig due to size reasons may not be able to and mud pumps, winches and other materials concentrated on the crawler chassis installation. Make the best use of everything, make the best use of people, so that we pursue the goal, as long as the reasonable, the most economic, the maximum optimization of drilling construction plan, the geological exploration task to complete, it can be. The rig is the main body to undertake the engineering task, and then make full use of the auxiliary materials.

6, the future development trend of crawler type full hydraulic drill.

If conditions permit, the development trend of belt separation is worth referring to, or to reiterate the concept of "the rig is the main body", and the application of belt separation technology in the appropriate occasions may provide more convenience for drilling operations.

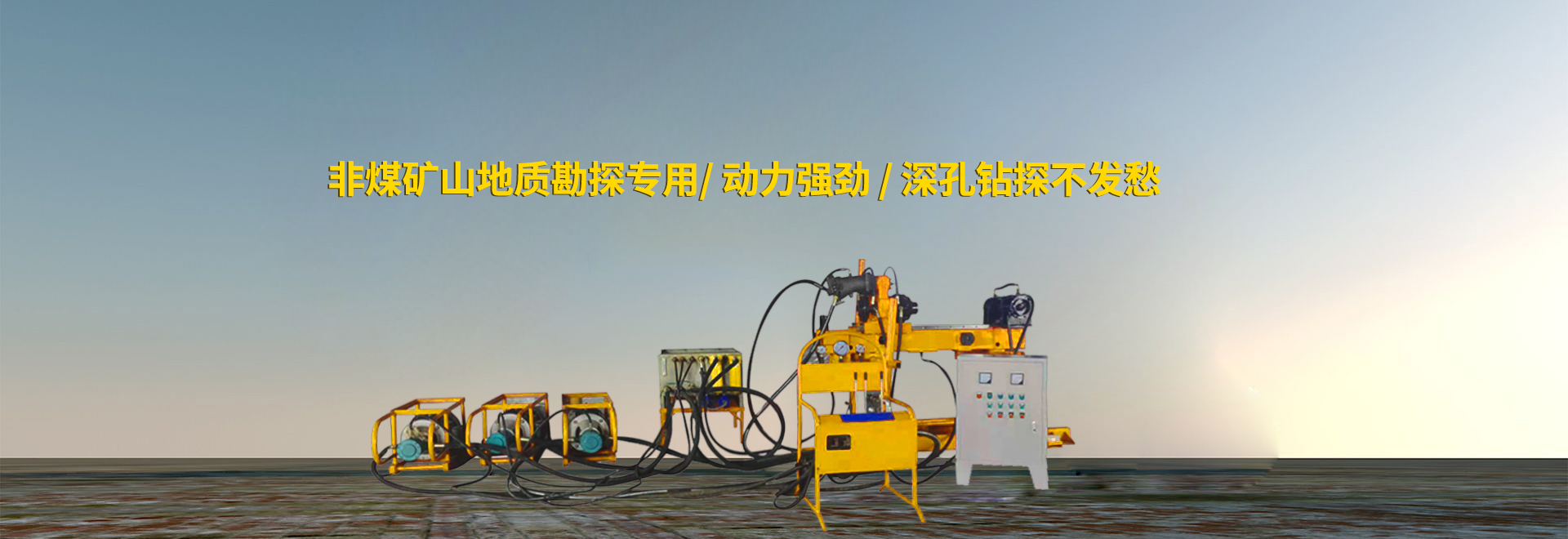

Chifeng Jixing drilling machine factory can provide professional improvement plans according to the needs of users, and combine the full hydraulic drilling machine products with crawler walking chassis.