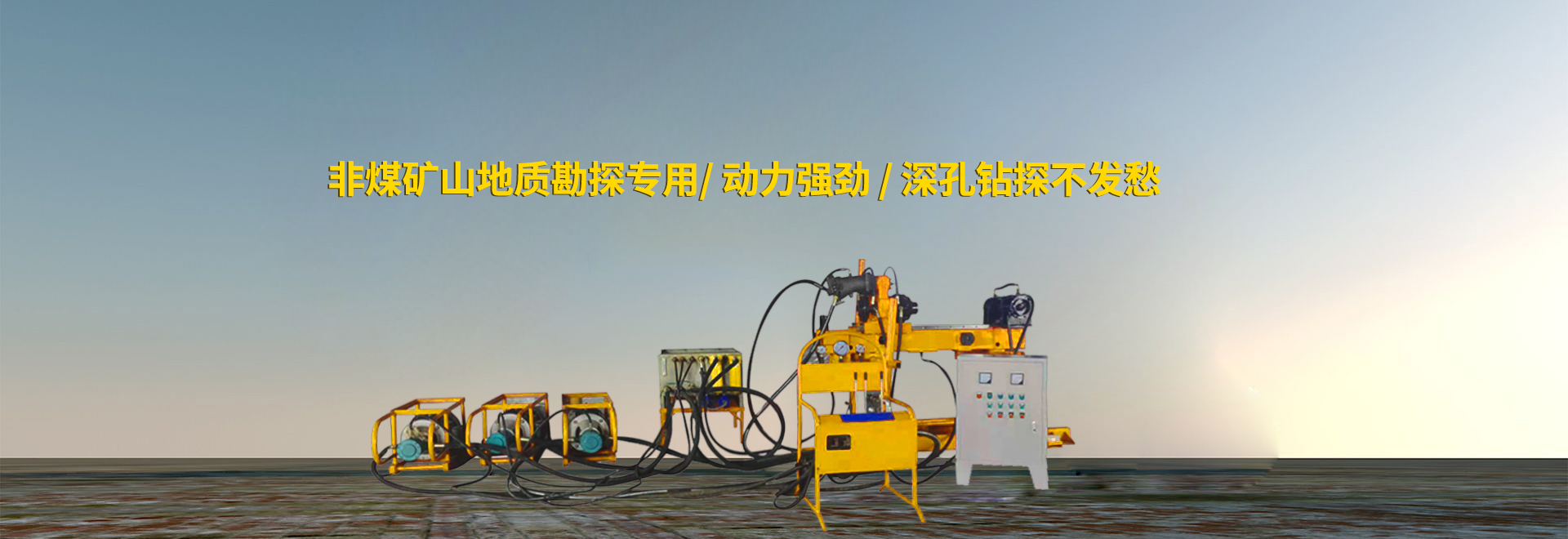

Referring to the full hydraulic portable drilling rig, it is a prospecting drilling rig product that has emerged in recent years and developed relatively fast. It is mainly used in non-coal mine surface exploration projects. It can be said that its birth on the vertical shaft surface drilling rig market is a relatively big impact, because it can have a larger drilling inclination range, while light, no bulky rig, but also save labor costs.

"It's easy to handle because it's light, and it's efficient because it's fast." This is the original intention and intention of the designer. So with all these fascinating advantages, are there any downsides?

1, we all know that in recent years, the price of the drilling market continues to fall, the price of contracted drilling projects is fixed, the problem comes, the price of portable drilling RIGS is relatively high, increasing the investment in fixed assets.

2, the top drive connection in the drilling period of the drill pipe will be shortened, when drilling the drill pipe in the hole will have a bending deflection, the drill pipe is easy to break, because it is a thin-walled drill pipe, so the material and heat treatment of the drill pipe requirements are relatively high.

3, rely on high speed to improve the efficiency of drilling, then the bearing lubrication of the rotating part is more critical, as we all know, the bearing should use oil lubrication at high speed, and the portable drill is grease lubrication, will aggravate the fatigue wear of the bearing, reduce the service life of the bearing, more easy to break.

4, the same is the technical barrier of the top drive design, more suitable for the downslope 35° to vertical downward orientation, not suitable for geological exploration of other azimuth holes.

5, can not adjust the output speed and torque force is a technical barrier to exploration under complex geological conditions, in the face of serious crushing, no water return, serious holes and hard formation, can not drill normally, thus can not reach the design hole depth.

6, a deep understanding of the definition of portable, that is, "convenient manual handling", we will find that the current portable drill, the top drive drill is getting bigger and heavier, and it is no longer portable, the reason is that the material and heat treatment process of the production enterprise can not meet the strength and durability requirements of the "full hydraulic" portable drill when working. Therefore, the functional gap can only be filled by making it bigger and stronger.

7, it is because of the backward material science and heat treatment process, so many parts of the "full hydraulic" portable drilling rig maintenance frequency is high, long time damage, such as and drill pipe connection under the machine wire. If the purchase price of spare parts remains high, the drilling project practitioners should be distressed.

8, the price of high quality is very high, the quality of the general price is also general, and the quality of the lowest price is also lower. This is currently in urgent need of upgrading and improving, not only with the national conditions, domestic industrial development level, supporting industries, economic development level, regional industrial structure is closely related to some frontier science. It is a development direction that needs long-term attention.

In short, no matter how good the existence of products, are inseparable from the market, we in the development of high-end drilling equipment at the same time, to try not to rely on imported technology and imported materials and imported processes. Domestically produced, more market-friendly products are more competitive products in the future.

The fully hydraulic tunnel prospecting rig produced by Jiexing Drilling Rig Factory in Chifeng also considers the design element of "portability". Think about it, why is the modular design required in the tunnel and good disintegration? Is not to consider when there is no auxiliary handling tools, it is convenient to rely on human handling? The modular design concept of tunnel core drilling rig needs to be implemented all the time, no matter what type of machine should be reflected.