Operation process, instructions, and steps of a fully hydraulic tunnel drilling rig

KY-500 type full hydraulic prospecting drill features specification

KY-500 tunnel prospecting rig is widely used in major metal mines and non-coal mines at home and abroad, Φ60, Φ75mm diameter rope core drilling project, is relatively mature and widely popularized full hydraulic tunnel prospecting rig products, but also the application of Φ60, Φ75 bore drilling basic model and start-up model, can meet most of the hole depth needs, cost-effective, It is the first choice of most users. The drilling depth of Φ75mm horizontal hole coring is not less than 420 meters, and the downward hole is not less than 500 meters.

1, according to different geological conditions, choose a more suitable spindle speed and output torque, effectively cope with broken, hard and other complex formations, so as to ensure drilling efficiency and drilling depth.

2, through the multi-channel reversing valve of the control console to achieve centralized hydraulic control, through the three operating handles to achieve normal drilling operations, drilling, lifting and pulling and twisting off the drill pipe and a series of operations.

3, modular design, split structure is suitable for installation and handling in the limited space environment in the tunnel.

4, can achieve 0°~360° arbitrary Angle of drilling coring work.

5, superior hydraulic linkage performance, to achieve the drilling, drilling, twist off drill pipe and other mechanical control, without manual unloading drill pipe; The gripper, master cylinder and chuck are responsive and do not damage the drill pipe, which greatly improves the working efficiency and the service life of the drill pipe.

6, in the limited space environment of the tunnel can achieve arbitrary inclination drilling, then in the open surface engaged in geological exploration operations more convenient, its installation and fixing method and full hydraulic portable drill the same, simple, easy to control.

7, the hydraulic system is the central system of the rig, the hydraulic station of the model oil return cooling effect is significant, the oil return resistance is small, can improve the system heating condition, so as to maintain the benign operation of the equipment. The filter precision of the tank is high, which can improve the service life of the motor, oil pump and other hydraulic actuator components and reduce the incidence of failure.

8, each motor in the distribution cabinet has a motor comprehensive protector, which can effectively prevent the failure caused by overload and lack of phase, and the control line is insured to prevent the distribution cabinet from burning; Equipped with ammeter and voltmeter, it can monitor the current and voltage of the main line, providing a stronger guarantee for drilling operations.

9, the use of advanced material and heat treatment process, the main structure part has higher precision, hardness and dimensional stability, thus improving the overall quality of the product.

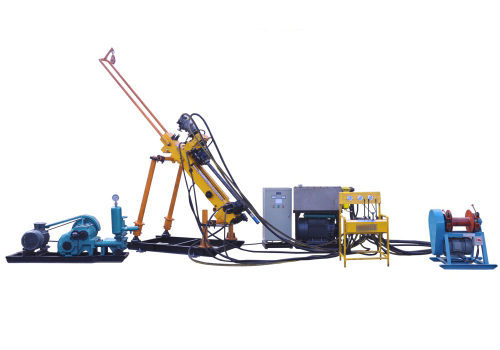

KY-500 full hydraulic prospecting drill picture display

KY-500 full hydraulic prospecting drill type parameter description

Drilling diameter (mm) Φ60 Φ75

Maximum drilling depth (m) 600 500

Core diameter (mm) 36 47.5

Coring method Common double or rope drill coring

Drilling azimuth 0° ~ 360°

Spindle output speed (r/min) 290-1000

Spindle output torque (Nm) 1100-260

Rated feed force (KN) 60

Rated lifting force (KN) 80

Rated pull speed (m/s) > 0.6

Oil supply mode Double gear pump oil supply

Oil pump model GPC4-80-32

Manual variable motor model L6V107MA

Rated power 45KW

Anti-wear Hydraulic Oil YB-N46/YB-N32 (Winter)

Machine weight (Kg) 1850

Device dimensions (L x W x H) mm Host 2050 x 580 x 800

Operation table 760×550×1050

Power car 1480 x 630 x 1200

Distribution box 600 x 250 x 1050

Recommended products of the same series

KY series full hydraulic tunnel drilling rig related news How much is a drilling rig? Drilling rig price? Drilling rig manufacturer?