In order to let the practitioners who are just in contact with drilling have a preliminary understanding of the full hydraulic tunnel prospecting rig or let the industry have a new understanding of the rig from a different Angle, here to talk about the principle of the rig and the functions of each part, not to do a tedious professional discussion that can be seen everywhere.

I. Overview of full hydraulic tunnel prospecting rig

The full hydraulic tunnel prospecting rig is a machine that drills holes on the working face of orebody and takes out the rock core by means of rotary drilling.

The motor rotates to drive the oil pump to discharge the high-pressure oil, which is centrally controlled by the multi-channel reversing valve on the operating table to supply oil to the chuck cylinder and realize the function of the power head clamping the drill pipe; Supply oil to the motor, drive the motor to rotate, and realize the rotation action of the power head; The feed action is realized by supplying oil to the main cylinder. This is the principle of rotary drilling.

While drilling the hole, the core remains in the inner tube system, and the core is removed by double-tube coring or rope coring, which is sequentially placed in the core box and recorded. This is a brief description of the drilling coring process.

Second, fully hydraulic drilling rig, tunnel drilling rig, rope core drilling rig functional description

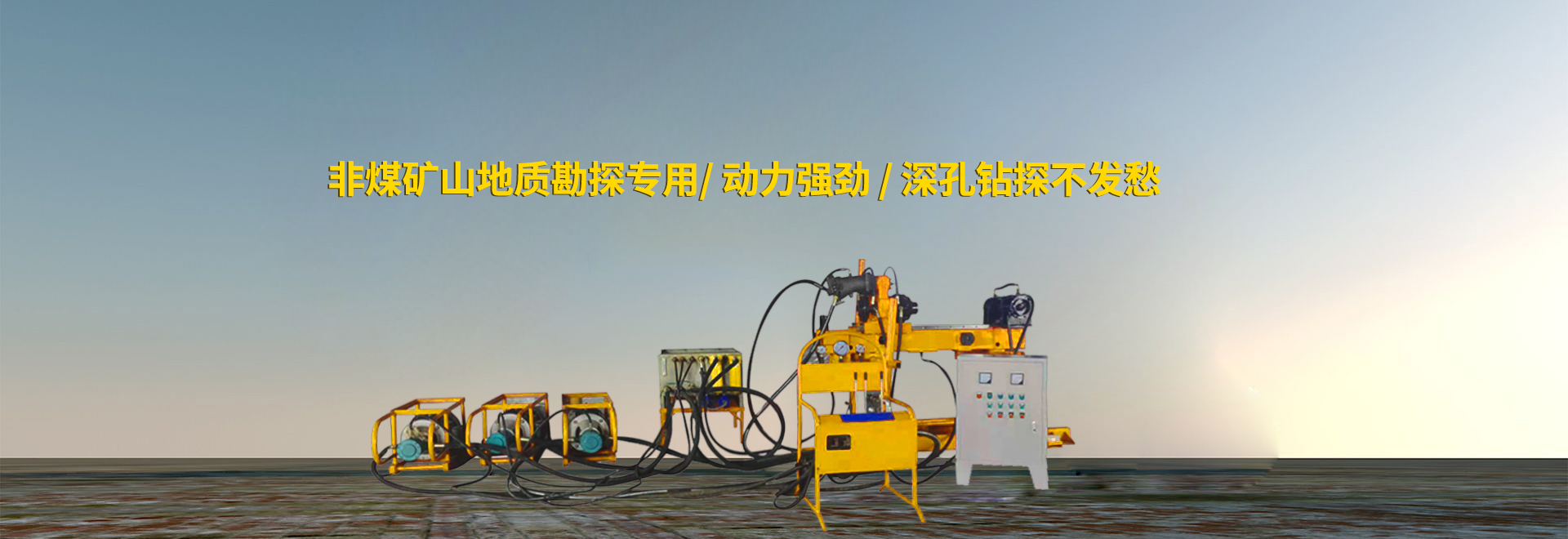

The full hydraulic tunnel prospecting rig is divided into four main parts: the main engine part, the power car part, the control console part, the distribution cabinet part, and the high pressure hose or cable connection between them.

1. The main engine part is the main part of the rig, which is composed of three parts: feed frame assembly, power head assembly and gripper assembly.

(1) The feed frame is a box-type structure, the main oil cylinder is fixed on the feed frame, and the slide board is driven by pulling to move on the feed frame slide rail.

(2) The power head part is that the motor is connected to the reducer box, and the rotary torque of the motor is increased by slowing down, while the cone-sleeve chuck is installed on the main shaft, and the relative motion of the chuck on the main shaft is driven by the small oil cylinder to achieve the clamping or loosening of the drill pipe.

(3) The gripper is a normally closed structure, that is to say, when there is no oil supply, the drill pipe is clamped by the elastic force generated by the pre-compression of the disc spring. When the high pressure oil is supplied, the disc spring is compressed again to make the gripper open and the clamp loosen the drill pipe.

2, the power car part is composed of fuel tank cooling, filter device and motor, oil pump drive device, motor rotation drive oil pump work, produce high pressure oil through the operation platform centralized control to reach the actuator components, drive the actuator work. Return the oil to the return oil filter through the tank to complete the filtration, through

After the tube cooler completes the cooling, it returns to the oil tank again, and is sucked into the oil pump again through the stability and precipitation of the oil tank to discharge the high-pressure oil.

3, the main body of the control console is a multi-way reversing valve, which is the control part of the full hydraulic tunnel drill and the central system. By pushing the handle to distribute high pressure oil to the executive parts, if the oil pump that provides the power source is the heart, then the multi-way reversing valve is like the brain, if from the perspective of the distribution of high pressure oil and the realization of the function, the multi-way reversing valve of the tunnel drilling rig is like the brain and like the heart.

① The handle that controls the rotation of the motor pushes the motor forward, the motor is reversed in the back, the motor does not turn when the valve stem is in the middle, and the high-pressure oil is discharged to the next valve. Whether it is fully open in the forward or reverse state, the oil of the first valve, that is, the oil of the large pump inlet valve, is only for the motor to rotate.

② The handle of the clamp valve plate is pushed forward, the high pressure oil is supplied to the rear cavity of the small cylinder, and the chuck is separately clamped the drill pipe; Pull the gripper back to open.

③ The operation handle of the feed valve plate is to control the high-pressure oil distribution to the main cylinder, the small cylinder and the gripper cylinder. Control two or three cylinders at the same time.

For example, when the transfer valve disc handle faces forward, that is, the drilling position, the motor turns on, then push forward to the inlet valve stem, the chuck is clamped the drill pipe, and the oil is supplied to the front chamber of the large cylinder, and the power head is fed.

Motor rotation does not open, when the rod is reversed, the transfer valve disc handle is in the forward position, push forward to the inlet valve stem, chuck clamp the drill rod, the gripper opens, and the power head moves forward; When the feed stem is pulled back, the gripper closes and clamps the drill pipe, the chuck opens and the power head moves back. This process is the process of drilling linkage. In turn, the handle of the transfer valve plate faces left, and we can achieve the de-drilling linkage and pour the drill pipe out of the hole.

④ By changing the direction of the handle of the valve disc, we can realize the linkage distribution of hydraulic oil.

⑤ Through the safety valve, we can set the rotary pressure value and the feed pressure value, which affects the rotary output torque of the motor and the thrust and tension of the cylinder; We usually say that the pressure regulator is actually a pressure reducing valve, which is to control the size of the feed pressure in the process of drilling.

4, the distribution cabinet part is to control the main motor of the rig and the mud pump motor start and stop, in a strict sense should be called the starting cabinet. Common starting modes include soft starting, autobuck starting and star triangle starting.

Soft start-up cost is higher; Autobuck starting actually does not allow the voltage to be too low, and a cabinet can only control the start and stop of one motor.

Star Triangle start is the most commonly used, affordable, safe and reliable way to start, the main motor, mud pump motor and winch motor can be connected in a distribution cabinet to control the start and stop.

On this basis, the starting cabinet of the full hydraulic tunnel prospecting rig has been upgraded and improved by Chifeng Jixing Drilling Rig Factory:

① The main line is equipped with ammeter and voltmeter, which can monitor the current and voltage of the total line.

② The control line is equipped with insurance to prevent the distribution system from being burned down due to failure.

③ In addition, zero row and ground row are configured.

④ Each motor is equipped with a motor comprehensive protector to prevent the motor from burning due to overload and lack of phase when working, which plays a comprehensive protection role.

⑤KY-600, KY-800, KY-1000 fully hydraulic drilling rig distribution cabinet also adds a remote wireless start function, can be in the 100 meters visual range of the main motor and mud pump motor for remote start.